Sekurufu sa carbide se kentsoeng ka mokhoa o ikhethileng

Tlhaloso

Dikurufu tsa CNC Torx ke mofuta wa sehokelo se kopanyang ho nepahala ha mochini wa CNC le ho tshepahala ha sistimi ya ho kganna ya Torx. Jwalo ka fektheri e etellang pele ya sehokelo, re ikgethile ka tlhahiso ya CNC ya boleng bo hodimo.screw ea torx e ikhethilengtse fanang ka ts'ebetso e ikhethang le ho tšoarella.

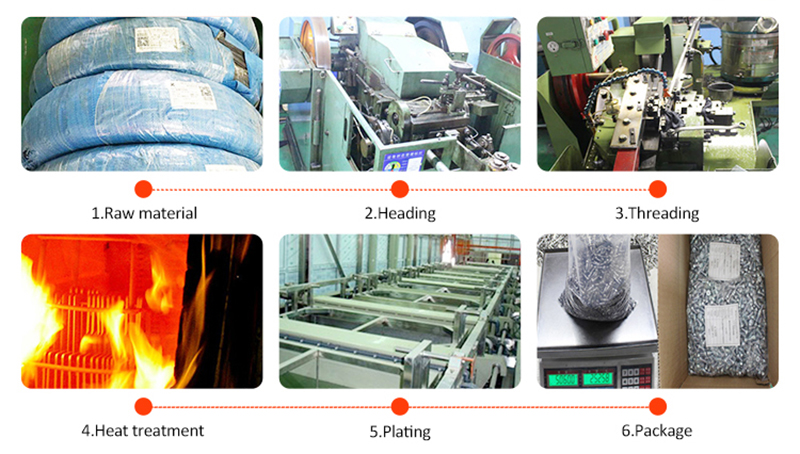

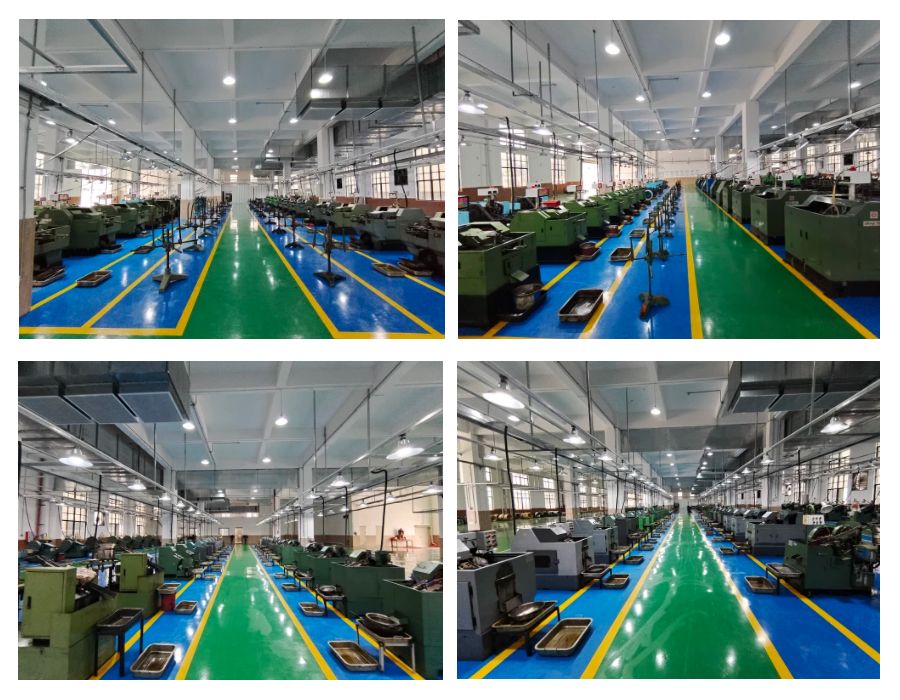

Ea ronaLi-screw tsa CNC Torxli etsoa ka hloko ho sebelisoa mekhoa e tsoetseng pele ea ho sebetsa ka CNC. Sena se netefatsa litekanyo tse nepahetseng, mamello e tiileng, le boleng bo tsitsitseng ho pholletsa le screw e 'ngoe le e 'ngoe e hlahisoang. Ka bokhoni ba rona ba ho sebetsa ka CNC, re ka etsa li-geometri tse rarahaneng le meralo e rarahaneng ho fihlela litlhoko tse thata ka ho fetisisa tsa kopo ea hau.

Sistimi ea ho khanna ea Torx e tsebahala ka ho tšoara ha eona hantle le ho hanyetsa ho tsoa ka har'a cam-out, e fanang ka tharollo e sireletsehileng le e sebetsang ea ho tiisa. Li-screw tsa rona tsa ho kenya carbide li na le sebaka se bōpehileng joaloka linaleli tse tšeletseng, se lumellang phetisetso e ntle ea torque le ho fokotsa kotsi ea ho hlobola kapa ho senya hlooho ea screw. Sistimi ea ho khanna ea Torx e fana ka tlhahiso e ntlafetseng, nako e fokotsehileng ea kopano, le ts'epo e ntlafalitsoeng ha e bapisoa le litsamaiso tsa khale tsa ho khanna.

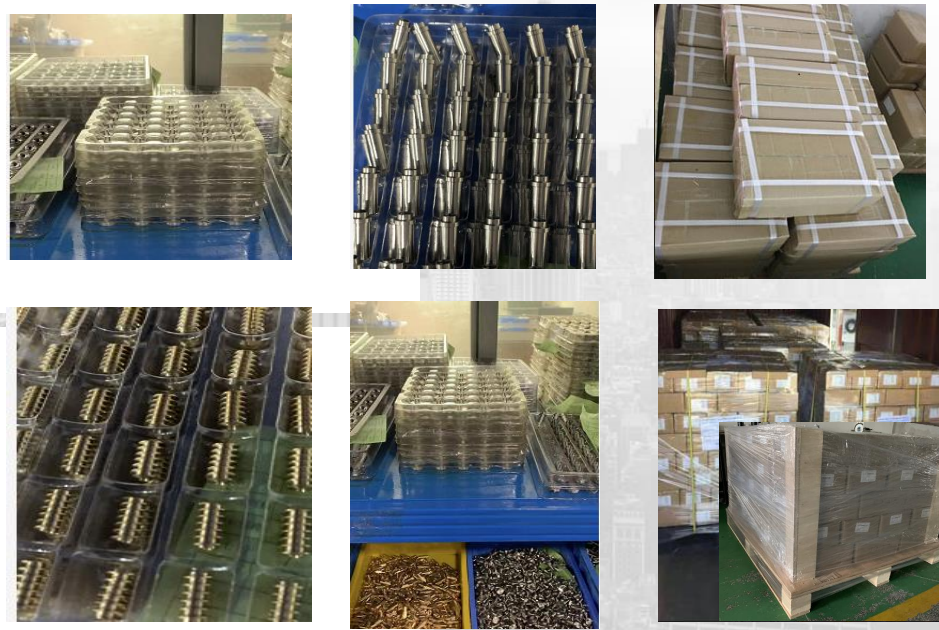

Rea utloisisa hore lits'ebetso tse fapaneng li hloka thepa e itseng le liphetho tse ikhethileng tsa bokaholimo. Ke ka lebaka leo re fanang ka mefuta e mengata ea thepa bakeng sa ronakenya dikurufu tsa torx, ho kenyeletsoa tšepe e sa ruseng, tšepe ea alloy, koporo, le tse ling. Ho feta moo, re fana ka liphetho tse fapaneng tsa bokaholimo tse kang zinc plating, black oxide coating, kapa passivation ho ntlafatsa ho hanyetsa mafome le botle. Sena se netefatsa horesekurufu sa torx sa hlooho e bataletsengli ka mamella tikoloho e thata le ho boloka botsitso ba tsona ha nako e ntse e ea.

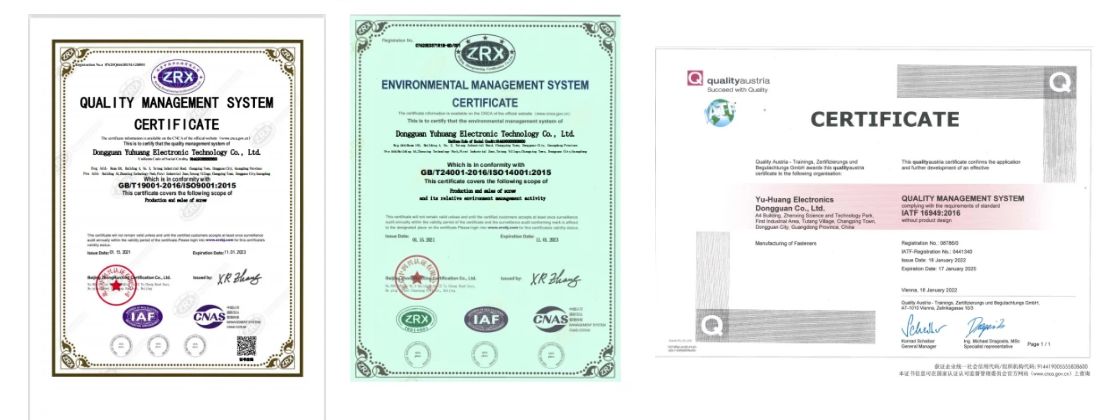

Fekthering ea rona, re beha khotsofalo ea bareki pele 'me re fana ka likhetho tsa ho iketsetsa ho fihlela litlhoko tsa hau tse ikhethang. U ka khetha ho tsoa boholo bo fapaneng ba khoele, bolelele le mekhoa ea lihlooho ho netefatsa hore e loketse kopo ea hau hantle. Re latela mehato e tiileng ea taolo ea boleng nakong eohle ea ts'ebetso ea tlhahiso, re etsa tlhahlobo e felletseng ho netefatsa hore sesebelisoa se seng le se seng se na ledikurufu tsa ho kenya khabidee fihlela maemo a holimo ka ho fetisisa a boleng le tshebetso.

ea ronasekerefe sa torx sa tshireletsofana ka mochini o nepahetseng oa CNC, ho tšepahala ha sistimi ea ho khanna ea Torx, mefuta e mengata ea thepa le liphetho, le likhetho tsa ho iketsetsa ho fihlela litlhoko tsa hau tse ikhethileng. Jwalo ka fektheri e tšepahalang ea li-fastener, re ikemiselitse ho fana ka li-screw tsa CNC Torx tse fetang litebello tsa hau mabapi le ts'ebetso, ho tšoarella le ts'ebetso. Ikopanye le rona kajeno ho buisana ka litlhoko tsa hau kapa ho etsa odara ea li-screw tsa rona tsa CNC Torx tsa boleng bo holimo.